Simetek repaired a gypsum screw for Yara. The project involved cutting, shaping and welding new screw blade preforms as well as machining the screw and balancing it dynamically. The length of the gypsum screw is 7,300 mm, its diameter 1,000 mm and mass 3,000 kg.

Simetek laser scanned and designed spillage chutes for a foaming plant. The material used for the chutes was hard surface plate Coroplate 143 6+4. The spillage chutes will be installed during a shutdown of the foaming plant.

Simetek manufactured and installed intermediate thickener spillage chutes for Yara.

Simetek will deliver a tipper cone to Yara. According to Jukka Holopainen, Installation Manager in the project, the design of the new cone is ready, and its manufacture is in process. The cone will be installed during a shutdown at the mine.

“We laser scanned the cone crusher site. Based on the scanning data, we prepared a plan for a fitting new cone. The bottom of the old cone will be shimmed, that is, evened out so that it is symmetrical. This is done by welding metal plates on the bottom of the cone, after which rubber plates are attached to the metal plates. The new cone will be fitted on the evened-out surface,” Holopainen explains.

The tipper cone will be manufactured of wear plate 450 HP.

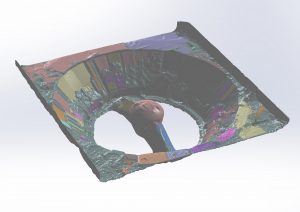

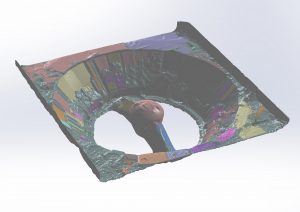

Simetek laser scanned, designed and manufactured steel structures for Boliden’s Kevitsa mine. The new steel structures were installed to an existing operation environment.

Simetek completed a 2.5-kilometre long DN500 x 12.5 mm tailings pipeline at Yara’s factory. The pipeline was pre-engineered partly at our machine shop and partly at the mine yard. The current piping will be replaced during a shutdown.

Simetek repaired a reactor screw for a major industrial operator by replacing the screw axle. The screw material was Hastelloy C276/Duplex 2205. The screw length was 10.5 m, its diameter 1,600 mm and mass 8,000 kg.

Simetek laser scanned the day silo of Agnico Eagle Finland Oy’s refinery. Using the scanning data, we devised a difference map for the replacement of wear plates. Simetek will continue monitoring the status of wear in the silo with regular laser scanning.

Simetek restored two mobile steam heater units for SteamPro. The project involved laser scanning the steam generator and the mobile unit frame. With the help of the scanning data, we fitted the unit with new steam generators, compressors, generators, pipeline, condensation water containers and water softening containers.