Simetek repaired the blades of stump crusher and re-fitted the bearings.

Simetek repaired the blades of stump crusher and re-fitted the bearings.

Simetek manufactured a cloak for a drying gas blower from fire-resistant hard-faced plate.

Simetek manufactured a lower slider for Junttan.

Simetek surface treated a ball mill for Elementis Minerals B.V. The ball mill weighs 55,000 kg. We had to demolish a wall to enable moving the mill into our premises. We also surface treated the mill’s bearing housings and toothed rim covers.

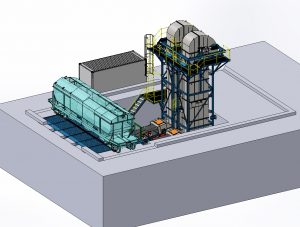

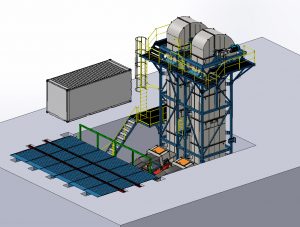

The design of Mussalo Harbour railroad wagon unloading equipment for Oy M. Rauanheimo Ab was commenced.

Simetek drilled the end plates of an acidproof steel (AISI316) heat exchanger for Ecomet Oy.

Simetek and Oy M. Rauanheimo Ab concluded a significant contract on the implementation of Mussalo Harbour railroad wagon unloading equipment in the late autumn.

Savo Vocational College student Tomi Leppänen enjoyed his internship at Simetek so much that he decided to continue working at the company through an apprenticeship.

Leppänen is a second-year student of production technology. He was accepted for an internship and apprenticeship at Simetek after contacting the company on the recommendation of his teacher.

Leppänen finds the industry interesting and suitable for himself. His favourite activity is turnery, and he has had plenty of opportunities to carry out lathe work at Simetek.

“Among others, I have manufactured cylinder mounting pins and various small components to finished products.”

In addition to turnery, Leppänen has had the chance to carry out milling and drilling for products delivered to customers. Leppänen has considered none of his tasks difficult, rather they have been fairly easy for him.

Leppänen compliments Simetek for its positive workplace atmosphere.

“My colleagues are friendly and offer help whenever required.”

Leppänen keeps his mind open to continuing his studies at a university of applied sciences in the future. However, his next step is to complete his current studies in production technology.

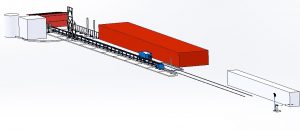

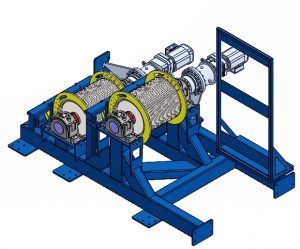

Simetek concluded an agreement with Kraton Chemical Oy on the turnkey implementation of a train car towing device. Simetek will design the device and install it at Kraton Chemical’s Oulu factory. In addition, the delivery includes electric automation and excavation work.

Simetek repaired the roller of a magnetic separator for Yara.